Importance of Regular Gas Furnace Maintenance

The Importance of Regular Gas Furnace Maintenance

As the chill of winter sets in, the reliability and efficiency of a gas furnace become critical for maintaining a warm and cozy home. Get ahold of All-Ways Heating & A/C for professional gas furnace repair . However, like any complex mechanical system, a gas furnace requires regular maintenance to function at its best. chimney inspection HVAC maintenance The importance of this upkeep cannot be overstated; it ensures safety, improves efficiency, extends the lifespan of the unit, and can even save money in the long run.

One of the primary reasons why regular gas furnace maintenance is essential is safety. A poorly maintained furnace can pose significant risks such as carbon monoxide leaks or fire hazards. Carbon monoxide (CO) is an odorless, colorless gas that can cause serious health issues or even death if inhaled in large quantities. During maintenance checks, technicians inspect the heat exchanger for cracks and ensure that all combustion gases are vented properly outside your home. They also check for any gas leaks that could be dangerous.

Efficiency is another key factor impacted by regular maintenance. When a furnace operates efficiently, it uses less fuel to generate heat, which translates into lower energy bills—a benefit every homeowner appreciates during cold months when heating costs spike. During maintenance visits, technicians will clean and adjust burner flames, inspect the blower motor, test for proper airflow, and replace dirty air filters—all actions that help maintain efficient operation.

The longevity of your gas furnace is directly influenced by how well it's maintained. Regular servicing prevents wear and tear from escalating into major breakdowns that can shorten the life expectancy of your unit. By addressing small issues promptly through routine checks and tune-ups—such as lubricating moving parts or replacing worn belts—homeowners can avoid costly repairs or premature replacement expenses.

Finally yet importantly is cost savings over time. Although there's an upfront cost to annual maintenance appointments, they're investments that pay off by preventing high utility bills due to inefficient operation or expensive emergency repairs caused by neglecting small problems until they grow larger.

In conclusion, regular gas furnace maintenance isn't just a recommendation; it's a necessity for homeowners who value safety, efficiency, longevity of their equipment—and their wallet’s well-being. It's advisable to schedule annual inspections with qualified professionals before each heating season begins to ensure peace of mind throughout those cold winter months when you depend on your gas furnace most.

Steps to Perform Basic Gas Furnace Inspection

Gas furnaces are a common heating solution in many homes, offering warmth and comfort during the cold months. However, just like any other appliance, a gas furnace requires regular maintenance to ensure it operates safely and efficiently. Understanding how to perform a basic gas furnace inspection can help homeowners maintain their systems and potentially avoid costly repairs or dangerous situations. Here is an essay discussing the steps involved in conducting such an inspection.

To begin with, safety is paramount when inspecting your gas furnace. Before you start any work, make sure to turn off the power supply to the unit to prevent any electrical accidents. If you're unsure about how to do this, consult your furnace's owner manual or contact a professional.

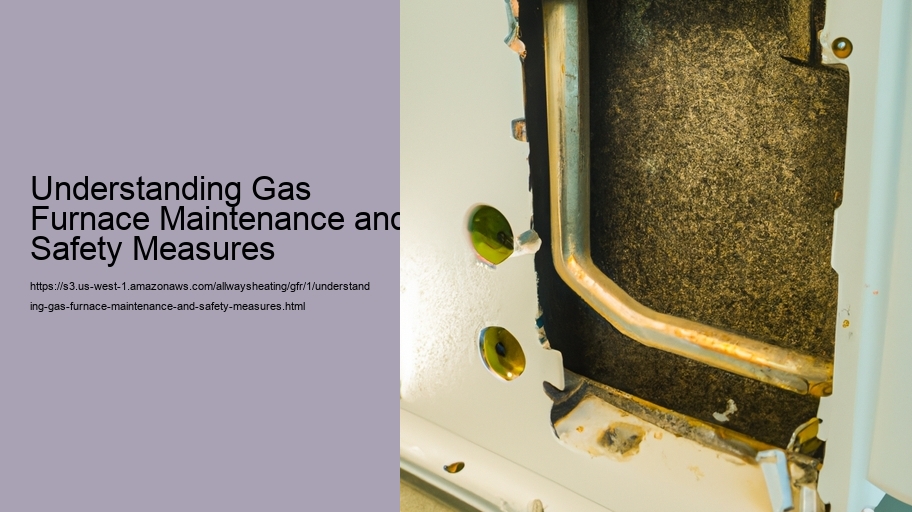

Once the power is off, start by examining the external parts of your furnace. Look for any signs of wear and tear on the body of the unit. Rust spots, dents, or loose panels can indicate potential problems that may need further investigation or repair.

Next, check air filters as they play a crucial role in maintaining good air quality inside your home while ensuring efficient operation of your furnace. Air filters should be inspected at least once every three months and replaced if they're dirty or clogged with debris. A clean filter allows for proper airflow and helps prevent dust from getting into mechanical parts of the unit.

The third step involves inspecting the thermostat since it regulates when and how much heat your furnace produces. Make sure it's functioning correctly by setting various temperatures and observing if there's an appropriate response from your heating system.

Moving on to internal inspections, visually examine the burners for cleanliness and proper alignment as dirty burners can cause inefficient burning which could lead to higher energy consumption or even carbon monoxide production. Also look out for any strange noises when turning on the burners; pops or bangs can indicate delayed ignition issues.

Another critical component is checking the heat exchanger for cracks which could leak harmful gases into your home environment. This part of your inspection should be done with great care; if you suspect any damage to this component, it’s advisable to call in a professional technician immediately as this poses serious health risks.

Inspect ductwork connected to your furnace as well for leaks that might affect its efficiency by allowing heat escape before reaching desired locations within your home. Sealing these leaks will improve performance significantly.

Finally, don't forget about vent pipes – they must remain clear all times so noxious gases produced by combustion process have safe exit route outside house structure instead accumulating indoors where they pose threat occupants’ health safety.

After completing these steps remember test functionality system overall making sure turns heats up expectedly without producing unusual smells sounds indicating malfunction somewhere workflow process machinery itself situation case again best course action would involve seeking help certified expert who diagnose resolve issue professionally effectively assuring peace mind throughout winter season ahead knowing family being kept warm risk-free manner thanks diligent approach toward basic gas furnace inspection routine maintenance efforts carried out responsibly conscientiously homeowner side equation here key longevity operational excellence one most important appliances found modern household today context understanding necessity ongoing vigilance comes equipment type particular given potential hazards associated misuse lack thereof terms regular upkeep procedures followed accordingly basis year after year without fail.

Cleaning and Replacing the Air Filter

Cleaning and replacing the air filter in your gas furnace is a simple yet crucial aspect of maintaining your heating system's efficiency and ensuring the safety of your home. The air filter's primary role is to capture dust, dirt, pet dander, and other airborne particles that circulate through your HVAC system. A clean filter not only helps in keeping the indoor air quality high but also prevents these particles from entering the furnace itself, where they can cause damage or reduce efficiency.

Over time, as the air filter does its job, it becomes clogged with the very contaminants it's designed to trap. This is when maintenance comes into play. A dirty air filter restricts airflow, forcing the furnace to work harder to circulate warm air throughout your home. This added strain can lead to increased energy consumption, higher utility bills, potential overheating, and even premature failure of furnace components.

To avoid these issues, it's recommended that homeowners check their furnace filters at least once a month during periods of heavy use (like winter), although this can vary depending on factors such as pets in the home or levels of outdoor pollution. If you hold up the filter and cannot see light passing through it or if there is an accumulation of debris visible on its surface, it’s time for a cleaning or replacement.

For washable filters (less common), cleaning involves rinsing them with water and letting them dry completely before reinserting them into the furnace. However, most residential furnaces are equipped with disposable filters that need to be replaced rather than cleaned.

When replacing an old filter, first ensure that you have purchased the correct size and type for your specific furnace model - this information is typically found in your furnace manual or printed on the existing filter's frame. With power turned off to prevent accidental fan engagement or electrical hazards during this process:

heat exchanger inspection 1. Locate your furnace’s filter housing which is usually near where cold air enters.

2. Slide out the old filter – take note of arrows indicating airflow direction so you can install new one correctly.

3. Insert new filter making sure it fits snugly without gaps around edges where air might pass unfiltered.

4. Dispose of old one properly.

5. Turn power back on after ensuring everything has been reassembled correctly.

This simple act of maintenance ensures not only proper functionality but also safety; a clogged filter could result in reduced airflow leading potentially to carbon monoxide build-up if combustion gases aren't vented properly due to lack of circulation.

In summary, regular inspection and timely replacement or cleaning of your gas furnace’s air filter are key steps in routine maintenance that promote efficient operation while safeguarding against unnecessary wear-and-tear and safety risks associated with poor ventilation and compromised indoor air quality.

Checking and Maintaining the Thermostat Settings

Checking and maintaining the thermostat settings is an essential aspect of understanding gas furnace maintenance and safety measures. The thermostat acts as the control center for your heating system, regulating indoor temperature and ensuring comfort in your home. Properly maintained thermostat settings can guarantee that your gas furnace operates efficiently, safely, and prolongs its service life.

Firstly, checking the thermostat involves verifying that it is accurately reading the room temperature. An incorrect temperature reading could lead to excessive or insufficient heating, causing discomfort and wasting energy. One way to test accuracy is by comparing the thermostat's reading with a separate room thermometer. If there are discrepancies, recalibrating the thermostat or replacing it might be necessary.

Maintaining correct thermostat settings also means inspecting for any signs of wear or damage. Older thermostats may have frayed wiring or dust accumulation that can affect performance. In such cases, cleaning or professional servicing may be required to ensure proper functionality.

Moreover, if you own a programmable thermostat, routine checks should include confirming that all programmed settings align with your daily schedule and seasonal adjustments. As seasons change, so do heating requirements; therefore adjusting the programming ensures maximum efficiency. For instance, during winter months when temperatures drop significantly at night, setting a lower temperature while you sleep can save on energy costs without sacrificing comfort.

Another critical safety measure is ensuring that the location of your thermostat does not compromise its operation. It should be placed away from direct sunlight, drafts, doorways, windows, and heat sources such as lamps or electronics which can mislead temperature readings and cause inappropriate furnace cycling.

Finally yet importantly is considering an upgrade to smart thermostats if you're still using older models. Smart thermostats offer advanced features like remote access through mobile devices and learning capabilities that adjust temperatures based on your habits over time—both contributing to better energy management and potentially lowering utility bills.

In conclusion, regular checking and maintaining of your gas furnace's thermostat settings are vital steps in safeguarding efficient operation while reducing risks associated with improper heating practices. This simple yet impactful task contributes substantially towards achieving a comfortable home environment while promoting safe and economical use of your heating system throughout its lifespan.

Inspecting the Heat Exchanger for Cracks or Damage

Understanding Gas Furnace Maintenance and Safety Measures: Inspecting the Heat Exchanger for Cracks or Damage

When it comes to maintaining a gas furnace, one of the most critical safety measures is the regular inspection of the heat exchanger for any signs of cracks or damage. The heat exchanger is an essential component of a gas furnace system as it separates the combustion process from the air that circulates inside your home. Its integrity is vital not only for efficient heating but also for preventing potential health hazards such as carbon monoxide (CO) leaks.

Over time, due to repeated heating and cooling cycles, metal fatigue can occur, leading to cracks in the heat exchanger. These cracks may be minuscule at first but can grow larger with continued use of the furnace. Even tiny fractures are significant because they can allow harmful gases including CO—a colorless, odorless and potentially deadly gas—to seep into living spaces instead of being safely vented outside.

A proper maintenance routine involves visual inspection of the heat exchanger which should be conducted by a qualified HVAC technician during annual service appointments. Advanced tools like borescopes—a type of flexible camera—may be used to inspect areas that are not easily visible. Additionally, technicians might perform tests using specialized equipment designed to detect traces of carbon monoxide leakage around the furnace.

If any damage or cracks are detected during an inspection, it is crucial that they are addressed immediately. Repairing a cracked heat exchanger isn't typically recommended due to safety concerns; replacement is often necessary to ensure continued safe operation. This underscores why regular inspections are not just about maintenance—it's also about peace of mind knowing that your home heating system isn't posing a risk to you and your family.

Furthermore, understanding how your gas furnace operates and recognizing warning signs can go a long way in ensuring safety between professional inspections. For instance, frequent headaches or flu-like symptoms among household members could signal CO presence in your home; so could excess condensation on windows or sooty stains near furnace vents.

In conclusion, inspecting the heat exchanger for cracks or damage is paramount when it comes to gas furnace upkeep and safety measures. It ensures that your heating system functions efficiently while safeguarding against hazardous emissions within your home environment. Homeowners should take this aspect seriously and ensure they engage with trustworthy professionals who can provide competent assessments and solutions if problems arise because ultimately, nothing trumps keeping our homes safe and warm without compromising on our well-being.

Testing Safety Features: Flame Sensor and Limit Switches

Gas furnaces are an integral part of many homes, providing warmth and comfort during the colder months. However, they also come with potential safety risks if not properly maintained. To ensure the safe operation of a gas furnace, it’s crucial to regularly test its safety features, particularly the flame sensor and limit switches. Understanding these components and their maintenance can prevent hazardous situations and prolong the life of your heating system.

The flame sensor is a small but critical component in a gas furnace that detects whether a flame is present when the gas valve is open. If no flame is detected, the sensor signals the furnace to shut down to prevent unburned gas from accumulating, which could lead to an explosion or fire hazard. Over time, the flame sensor can become coated with soot or other debris, causing it to malfunction by either failing to detect a flame when one exists or not shutting off the gas supply when needed. This makes regular cleaning and testing of this component essential for safety and efficiency.

Testing a flame sensor typically involves checking its condition visually for any obvious signs of wear or damage and then using a multimeter to measure its electrical resistance while the furnace is operating. If readings fall outside manufacturer specifications or if visual inspection shows extensive corrosion or damage, replacement may be necessary.

Limit switches serve another vital role in maintaining safe furnace operation. These switches monitor the temperature within various parts of your heating system, such as near burners and heat exchangers. Their primary function is to prevent overheating that could damage components or potentially cause fires by turning off the burner if temperatures exceed preset limits.

Regular testing of limit switches involves evaluating their response to temperature changes within your heating system. A technician will often simulate overheating conditions safely during routine inspections to confirm that each switch activates correctly at designated temperature thresholds—shutting down fuel supply and fan operations as designed—and resets once temperatures return to normal levels.

To maintain these safety features adequately:

1. Schedule annual professional inspections: An HVAC technician has the tools and expertise required for thorough testing.

2. Keep air filters clean: Blocked filters restrict airflow leading to overheating which can trigger limit switches unnecessarily.

3. Ensure proper ventilation around your furnace: Obstructions can cause heat buildup putting unnecessary strain on limit switches.

4. Stay vigilant about strange noises or smells coming from your furnace: They could indicate problems with combustion that may affect both sensors’ performance.

In conclusion, regular maintenance checks—including testing safety features like flame sensors and limit switches—are non-negotiable aspects of owning a gas furnace; they safeguard against dangerous malfunctions while ensuring efficient operation throughout winter months. As homeowners rely on their furnaces for comfort during cold weather spells understanding how these important components function provides peace mind knowing their household remains protected against potential hazards associated with gas heating systems

Professional Maintenance: When to Call a Technician

Professional maintenance of your gas furnace is not just about ensuring efficient operation; it's also a critical component of home safety. Gas furnaces, while commonly used and generally safe when properly maintained, can pose serious risks if neglected or improperly handled. Understanding when to call a technician for gas furnace maintenance is essential for both the longevity of your heating system and the safety of your household.

Firstly, routine annual inspections are imperative. These inspections should be conducted by a certified HVAC technician who will check the overall health of your furnace. They'll look at the heat exchanger for signs of corrosion or cracks, which could lead to dangerous carbon monoxide leaks. They'll also clean and inspect burner parts, ignition systems, and safety controls.

Secondly, if you detect any unusual sounds such as banging, popping, rattling, or screeching coming from your furnace, it's time to call in a professional. These noises may indicate mechanical problems that could compromise efficiency or even pose a risk of fire.

Another sign that demands immediate attention is the smell of gas in or around your furnace. This could suggest a gas leak. If you notice this scent—often described as rotten eggs—evacuate the area immediately and contact emergency services before calling in technicians to handle repairs once the area has been deemed safe.

It's also wise to seek professional help if you're experiencing persistent issues with heating performance. This might include uneven heating across different rooms or an unresponsive thermostat. Such symptoms can point to underlying problems only a trained eye can diagnose accurately.

Moreover, visible signs like soot around the furnace or excessive moisture on windows and walls within the home can be indicators that your gas furnace isn't operating correctly and needs inspection by an expert.

Lastly, if you've skipped yearly maintenance appointments and suddenly realize it’s been over a year since a technician last checked your system—if not longer—it’s time to schedule service without delay.

In conclusion, recognizing when professional maintenance is needed for your gas furnace involves understanding both routine scheduling requirements as well as being vigilant about signs of potential malfunctioning. Regular inspections by qualified technicians ensure that small issues can be caught early before they turn into big problems while maintaining optimal safety standards within your home environment.

Carbon Monoxide Detectors: Installation and Monitoring

Understanding the importance of gas furnace maintenance and safety measures is crucial for every homeowner or occupant. One key aspect of ensuring a safe and well-maintained heating system is the installation and monitoring of carbon monoxide (CO) detectors. Carbon monoxide is a colorless, odorless gas that can be fatal at high levels, and it's often produced by malfunctioning fuel-burning appliances like gas furnaces.

To protect against the dangers of CO poisoning, installing carbon monoxide detectors near your gas furnace and in living areas is essential. These devices work similarly to smoke alarms, alerting you with an audible signal when high levels of carbon monoxide are present in the air.

When installing CO detectors, there are several important considerations to keep in mind. First, ensure that at least one detector is placed on each level of your home, including the basement if you have one. It's recommended to install them near sleeping areas so that they can wake up occupants in case of an emergency during the night. Additionally, place them at least 15 feet away from fuel-burning appliances to prevent false alarms caused by brief emissions during appliance startup.

For optimal effectiveness, follow the manufacturer's instructions regarding placement height—some detectors are designed to be installed on walls at a certain height while others may be suitable for placement on ceilings. Avoid locations where curtains or furniture could obstruct airflow to the detector or where they might be exposed to direct sunlight or drafts from windows and doors as these factors could affect their operation.

Once installed, regular monitoring and maintenance of your CO detectors should become part of your routine home safety checks. This includes testing the units monthly using the test button feature most models come equipped with and replacing batteries annually unless you have detectors with sealed long-life batteries which will require less frequent replacement.

Furthermore, note that CO detectors have a limited lifespan—typically five to seven years—after which they must be replaced even if they appear functional because their sensing technology deteriorates over time. Always check for an expiration date on your unit or consult with the manufacturer if unsure when it needs replacing.

In conjunction with having functioning CO detectors, regular maintenance of your gas furnace by a qualified professional is critical for preventing carbon monoxide issues before they arise. This includes annual inspections before the heating season begins wherein technicians check for leaks or blockages in vents and flues, examine heat exchangers for cracks through which CO could leak into indoor air spaces, replace filters as necessary among other tasks all aimed at ensuring efficient and safe operation.

In summary, properly installing and diligently monitoring carbon monoxide detectors play a vital role in maintaining household safety around gas furnaces. By combining these steps with regular professional maintenance checks on your heating system, you can enjoy warmth without compromising on health risks associated with exposure to this deadly gas.